LusiveLife

LusiveLife /

Design - Events - Giving - InspirationMind-Blowing Architectural Details with 3D Printing

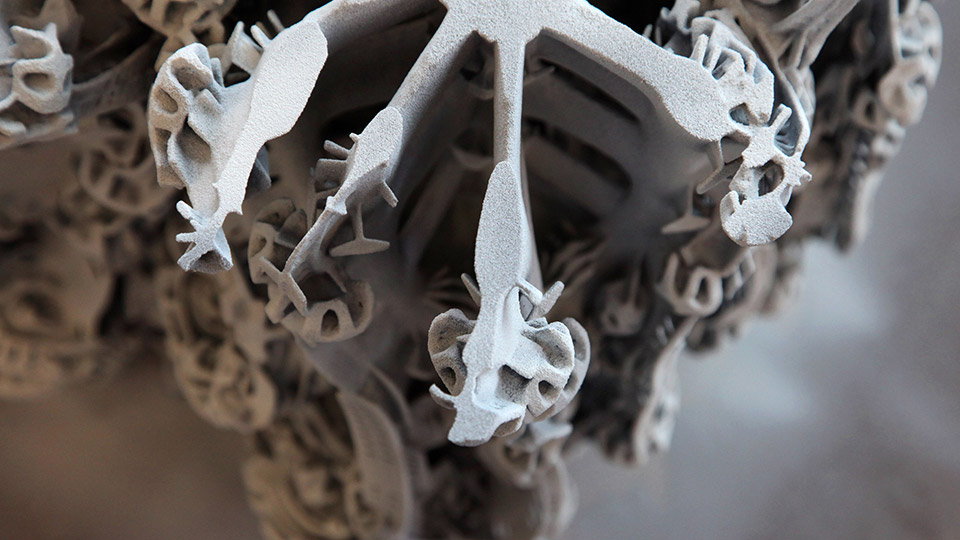

"Digital Grotesque" consists of two full-scale 3D printed grottos. Created by architects Michael Hansmeyer and Benjamin Dillenburger, the newest edition, "Grotto II," is a commission by Centre Pompidou, and recently premiered for the Centre Pompidou in Paris. It is a highly ornamental structure out of 7 tons of printed sandstone that demonstrates how computational design and additive manufacturing can make new architectural worlds tangible.

The grotto is entirely designed by algorithms, and optimized to present highly differentiated geometries that forge a rich and stimulating spatial experience for the observer. A subdivision algorithm exploits the 3D printer’s full potential by creating porous, multi-layered structures with spatial depth. A single volume spawns millions of branches, growing and folding into a complex topological structure. Hundreds of square meters of surface are compressed into a 3.5 meter high block that forms an organic landscape between the man-made and the natural.

In the Digital Grotesque project, algorithms are used to create a form that appears at once synthetic and organic. The design process thus strikes a delicate balance between the expected and the unexpected, between control and relinquishment. The algorithms are deterministic as they do not incorporate randomness, but the results are not necessarily entirely foreseeable. Instead, they have the power to surprise.

Digital Grotesque takes additive manufacturing technology to a true architectural scale. Not a small model is printed, but the actual room itself. Digital Grotesque presents a fully immersive, solid, human-scale enclosed structure with a perplexing level of detail. Its geometry consists of hundreds of millions of individual facets printed at a resolution of a tenth of a millimeter, constituting a 3.2-meter high, 16 square meter large room.

The potentials of additive manufacturing in architecture are enormous. Architectural details can reach the threshold of human perception. There is no longer a cost associated with complexity, as printing a highly detailed grotto costs the same as printing a primitive cube. Nor is there a cost for customization: fabricating highly individual elements costs no more than printing a standardized series. Ornament and formal expression are no longer a luxury – they are now legitimized.

With additive manufacturing, architectural design can be performed entirely in three dimensions without a need for plans, sections, and construction drawings. There are almost no fabrication constraints.